Aerosol filling machines are vital within the manufacture of several spray-centered items, from deodorants to spray paints. These equipment streamline the production process, making certain precision, consistency, and security. Essential devices Within this class incorporates the aerosol crimping machine, aerosol gas filling machine, and specialized gadgets such as the spray paint can filler and deodorant filling device. This article explores their functions, programs, and relevance in the commercial landscape.

Aerosol Crimping Devices: Making certain a Secure Seal

The aerosol crimping equipment performs a significant purpose in sealing aerosol cans. This device crimps the valve on the can, creating a protected and airtight seal to circumvent leakage and manage product integrity. Exact crimping is significant for making sure the protection and functionality of the aerosol product, specifically for pressurized contents like sprays and gasoline-primarily based formulations.

Gas Filling Equipment for Aerosols

The aerosol gasoline filling device is made to fill cans with propellants, that are crucial for dispensing the products to be a high-quality mist or spray. These devices handle gases like hydrocarbons, CO2, or nitrogen with precision, making sure the right pressure and quantity for each can. Advanced fuel filling machines greatly enhance generation efficiency though retaining safety criteria in dealing with flammable or pressurized gases.

Spray Paint and Deodorant Filling Equipment

Specialized equipment just like the spray paint can filler and deodorant filling equipment cater to niche apps during the aerosol sector.

Spray Paint Can Filler: This equipment makes certain specific filling of Filling Machine For Liquid paint merchandise, accounting for the viscosity and necessary regularity of spray paint. It ensures that each and every can is crammed uniformly to fulfill high quality specifications.

Deodorant Filling Device: These devices are optimized for managing liquid deodorants as well as their associated propellants, ensuring accurate filling, crimping, and sealing for buyer-All set products and solutions.

Aerosol Spray Machines and Liquid Filling Equipment

The aerosol spray equipment encompasses a range of functionalities, from filling to crimping and testing, making it an all-in-a single Resolution for aerosol generation traces. Equally, the filling equipment for liquid is multipurpose, effective at managing many liquids throughout industries, together with cosmetics, food, and pharmaceuticals.

Great things about Aerosol Filling Equipment

Precision: These equipment assure precise filling and sealing, reducing solution Aerosol Spray Machine wastage.

Effectiveness: Automated systems increase output velocity and lessen labor fees.

Safety: Sophisticated designs ensure Safe and sound dealing with of pressurized and flammable components.

Versatility: From paints to deodorants, these equipment accommodate a wide array of items.

Summary

Devices much like the aerosol crimping machine, aerosol fuel filling machine, and specialized niche alternatives such as the spray paint can filler and deodorant filling equipment are indispensable in nowadays’s manufacturing landscape. They enrich effectiveness, maintain merchandise top quality, and ensure basic safety in aerosol production. As industries continue on to innovate, these machines will remain for the forefront, driving breakthroughs in packaging and product shipping and delivery.

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Anthony Michael Hall Then & Now!

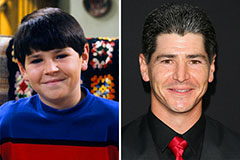

Anthony Michael Hall Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Shane West Then & Now!

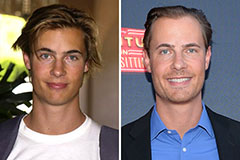

Shane West Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now!